At the dawn of fourth industrial revolution, work has changed profoundly and new jobs have been introduced.

Today we must make sense of humans and robots working shoulder to shoulder to achieve organizational goals and support each other.

In my earlier post, I related how technology successfully blends into our environment and assists us in seamlessly performing our tasks. The same is true for the technology used on factory floors in the new industrial era. In this post, I will offer my perspective on the fourth industrial revolution and address some of the most commonly raised questions.

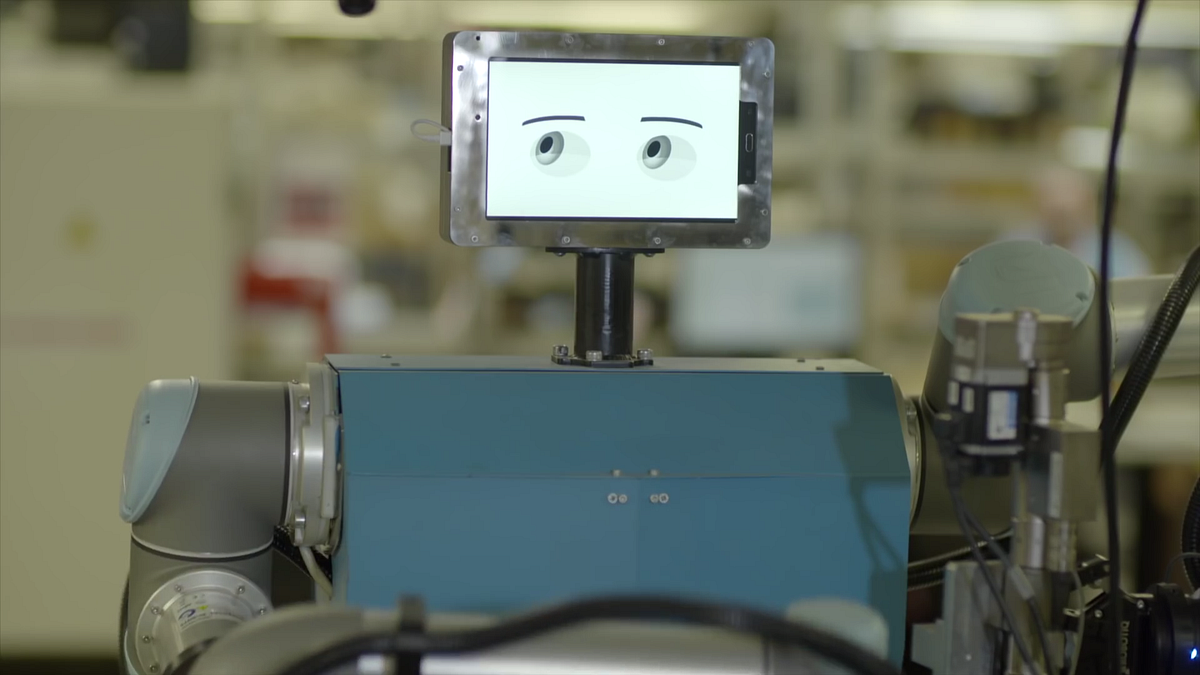

Collaborative human-robot assembly line

Social aspects of robot adaptation in working with humans @Atölye 4.0.

The first three industrial revolutions changed the way we approach manufacturing. And every industrial revolution changes the way we work. During the first industrial revolution, when machines were introduced to manufacturing, we went from heavy physical labor to operator-type personnel. We then started to measure almost everything in terms of the amount of machine work per time unit. The Maximization of this metric lead to the second and third industrial revolution.

By the beginning of 21st century, metrics related to the manufacturing capacity and quality of final products skyrocketed. The manufacturing paradigm was set to change once again. Now we are after different metrics. Perhaps we can correct the mistakes we made as we barged towards the production goals of the first three revolutions.

So, how is the fourth industrial revolution different from its predecessors?

We will explore the answer from three different perspectives; the popularization of smart assistance systems, cognition-based automation, and social robotics.

Smart Assistance Systems

Smart assistance systems are software workforce systems used by organizations in the new industrial revolution. These systems perform the automation of high volume, repetitive, and manual tasks previously executed by white-collar employees. Work performed by smart assistance systems, also known as robotic process automation, involves not industrial robots but software robots capable of automating workflow and replicating user activity. Compared to cognition-based automation or social robotics, smart assistance systems deal with much simpler tasks that don’t require reasoning. Thus, we may not always relate artificial intelligence to them. These systems are already in place in businesses like call centers.

In the fourth industrial revolution, these smart assistance systems will become the indispensable part of the workforce, allowing employees to focus on more creative, innovative, and interesting tasks

that software cannot perform. As a result, work will be more interesting and motivation will definitely increase.

Cognition Based Automation

Cognition-based automation builds on smart assistance systems and helps automate high volume, repetitive tasks that need a certain amount of knowledge, understanding, or insight. Task-related knowledge of such systems is comparable to human understanding thanks to artificial intelligence. Main characteristics of cognition based automation are recognition of patterns, images, text, and handwriting; natural language processing, semantic computing, and probabilistic inference. Over time, the machine learns algorithms to enhance systems, detect patterns, and build on previous experience. Cognition-based automation is purely software and usually has no physical interface. In the fourth industrial revolution, administrative work in various public and private industries will be performed by these type of automation systems. On the other hand,

work performed by humans will take a different direction: supervising these systems and collaborating with them to accomplish even more complex tasks. Human intelligence will dominate.

High skilled work will evolve on a larger scale.

Social Robotics

For me personally, the most exciting and least explored area of research is social robotics. Social robotics will profoundly change our work. As opposed to smart assistance and cognition-based automation systems, social robots are physical creations, not just software systems per se. Social robots can interact, communicate, and collaborate with humans and other social robots to complete complex tasks. They use sensors for cognition, artificial intelligence for reasoning, and intelligent actuators for physical interaction.

We will reap the benefits of social robots in the fourth industrial revolution. They will be given full autonomy while working shoulder-to-shoulder with humans, supporting each other to achieve organizational goals.

Social robots are put in place not to steal jobs from humans, but to serve as “co-pilots” by augmenting our cognitive, computational, and physical abilities. Social robots are ever-evolving, artificial intelligence-based learning agents that are continuously “trained” by observing human actions in various situations.

Concluding Remarks

At the dawn of the fourth industrial revolution, the nature of work is profoundly changing and new jobs are emerging Employees are enabled to perform highly-skilled tasks both in the office and on the factory floor, with smart assistance systems, cognition-based automation, and social robotics. As the nature of work and the work environment transform, employees will enjoy greater responsibility and broader personal development. It is important that we embrace the new industrial revolution today, ask ourselves what we want our future workplace to look like, and then create tools and technologies to realize it. Now is the time for humans to reclaim their central role in manufacturing.

TR

TR

Rethinking Work for

New Industrial Era